Finishing Lab

We offer our customers the convenience and reliability of a full on-site finishing lab. Our state-of-the-art lab allows us to provide quick service without ever compromising on quality, ensuring you get the perfect pair of glasses faster.

Having a full finishing lab onsite means we can control every step of the eyewear creation process, from start to finish. We use the latest technology and equipment to ensure precise cuts and finishes, guaranteeing that your glasses are made to the highest standards. Whether you need special coatings, tints, or specific lens designs, we can handle a wide range of customizations to meet your unique needs.

Lab Equipment & Expertise

We are proud to feature best-in-class equipment in our in-house finishing lab to ensure the highest level of quality.

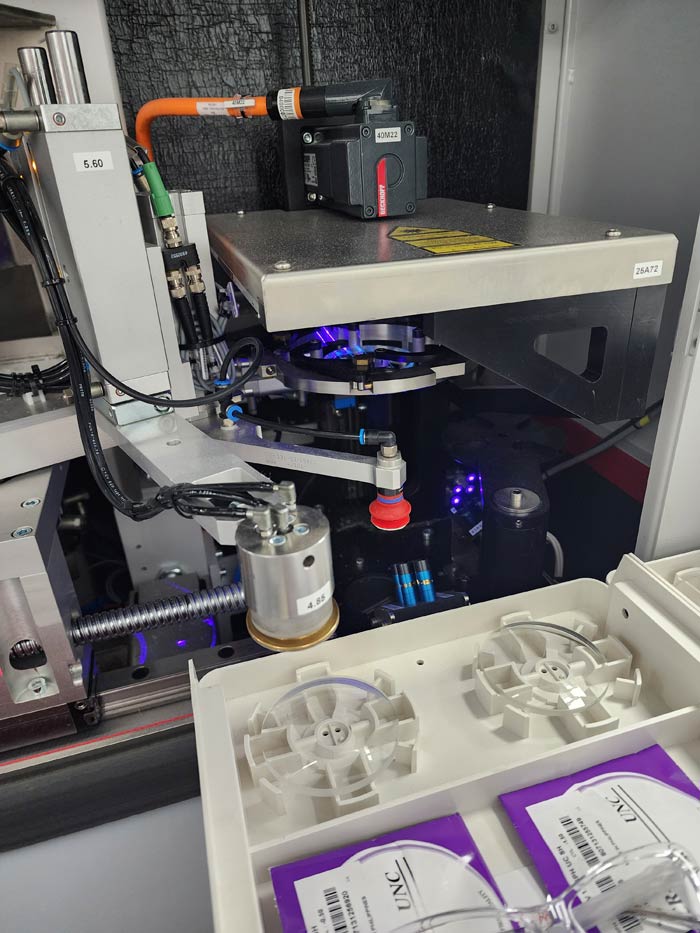

XRT Lens Fabrication Device

Every lens is processed through the XRT Lensmaker. At the core of the XRT Lensmaker’s automated precision shaping system is a polycrystalline diamond instrument, crafting lenses with up to eight microns precision without elliptical discrepancies.

More about XRT Lensmaker

This device shapes polycarbonate, high-index, and CR39 without needing adjustments or recalibration for each material type. The XRT Lensmaker ensures our operational efficiency and excellence, embodying our commitment to meeting your specific optical requirements.

Acuity Lens Surfacing System

The Acuity Plus Lens Surfacing System generates exceptionally accurate lenses. Our team can select the best processing times and pressures based on the specified lens material: CR-39, polycarbonate, hi-index, or glass. This degree of precision is supported by a mechanical design that provides optimized fining and polishing orbits.

Triumph 3D Edger

The Triumph 3D Edger is an award-winning system which automatically maps the thickness and front and back curvatures of a lens in less than eight seconds.